Home » Industries » Manufacturing » A push towards smaller batch sizes

Visual manufacturing solutions

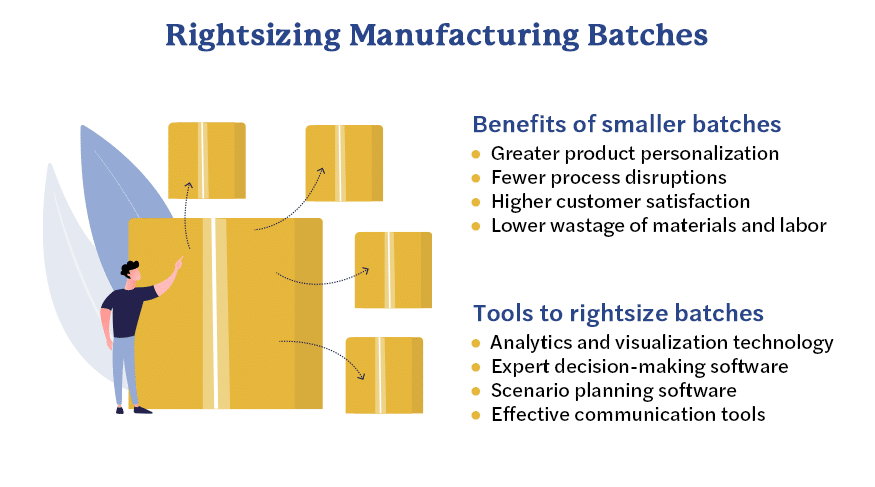

Analytics and visualization form the first area where technology is helping address those new challenges. You need analytics for those powerful visualizations to understand what's going on where. They include tools like visual manufacturing execution systems (MES), which allow for a visualized rendering of entire manufacturing value chains from the upstream raw material source to the end consumer.

Expert decision-making software is another tool that manufacturing companies are investing in. Essentially, that is intelligent automation, where applications detect problems and recommend solutions.

Scenario planning software is also witnessing increased traction, and manufacturing companies are using that to crunch historical data to prepare for future eventualities. The pressure today is on their PLM software to get the configurations right in their scenario planning and share that data in a meaningful way with their partners. Instant exchange of information is enabled through APIs, so they have to be able to play in the API economy as well.

The product itself is not going to sell anymore. In the coming years, manufacturers have to ensure that their products are available in the right digital channels. Web-based interfaces allow manufacturers to connect industrial controls on the shop floor to the end-consumer.

Key takeaways

- COVID-19 disruptions are compelling manufacturers to produce smaller batches that they can produce safely.

- The changed environment is driving investments in analytics and visualization, and in strengthening PLM software.

- APIs and digital channels are facilitating the push towards personalization.

Contact

Our experts can help you find the right solutions to meet your needs.

Get in touch